Your cart is currently empty!

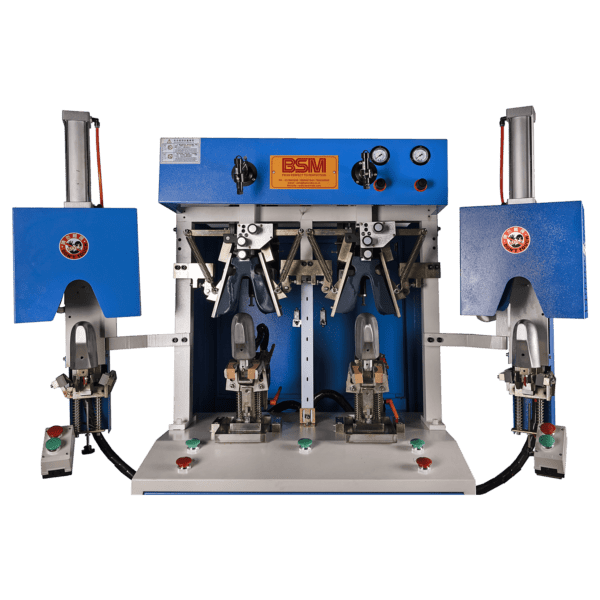

Counter Moulding Machine (Hot & Cold)

The Counter Moulding Machine is an innovative and versatile tool for molding the back part of footwear. It features adjustable lasts, automatic temperature regulation, projection lamp, and an environmental freezing system, ensuring precise and consistent results for various types of footwears.

Description

- Hot and Cold System: The machine’s advanced hot and cold system enables the molding of any type of counter stiffener, ensuring versatility and flexibility in the production process.

- Adjustable Lasts: The adjustable lasts can be tilted, providing ease of operation and allowing for precise and customized molding of different footwear designs.

- Automatic Temperature Regulation: The Counter Moulding Machine comes equipped with automatic temperature regulation for both inner and outer molds. This feature ensures optimal molding conditions for various materials, resulting in superior end products.

- Projection Lamp: The built-in projection lamp assists operators in achieving accurate and precise molding positions, enhancing the efficiency and effectiveness of the process.

- Environmental Freezing System: The cooling mold incorporates an environmental freezing system that can reach temperatures as low as -30 degrees Celsius, ensuring efficient and effective cooling of the molded parts.

- Adjustable Pressure and Timing: The machine allows for easy adjustment of pressure and timing, accommodating different types of footwear products and specific molding requirements.

Specifications

| Model No. | BS-516 |

|---|---|

| Dimension | 890 x 1480 x 2000mm |

| Weight | 600 Kg |

| Voltage | 220V/50HZ |

| Power | 2.7 kW |

| Air Pressure | 0.6 Mpa |

| Capacity (Pairs/8hr) | 1500 |

Maintenance

- Regularly clean and lubricate the machine to prevent dust and dirt from building up, which can cause damage or malfunction.

- Inspect the machine regularly for any signs of wear and tear or damage, and promptly address any issues that are identified.

- Follow the manufacturer’s recommended maintenance schedule for the machine, including regular oil changes and filter replacements.

- Only use the machine for its intended purpose, and do not exceed its stated capacity or capabilities.

- Train all operators on how to safely and effectively use the machine and ensure that they understand the importance of following proper maintenance procedures.

Safety Considerations

- Ensure that the machine is properly grounded before use to prevent electrical hazards.

- Do not operate the machine without proper training or authorization.

- Keep hands and loose clothing away from moving parts of the machine.

- Turn off the machine and disconnect it from its power source before performing any maintenance or repairs.

FAQs

Can I see a demo of the machine before I buy it?

What is the life of the machine?

What is the warranty period for your machines?

Load More