Your cart is currently empty!

Description

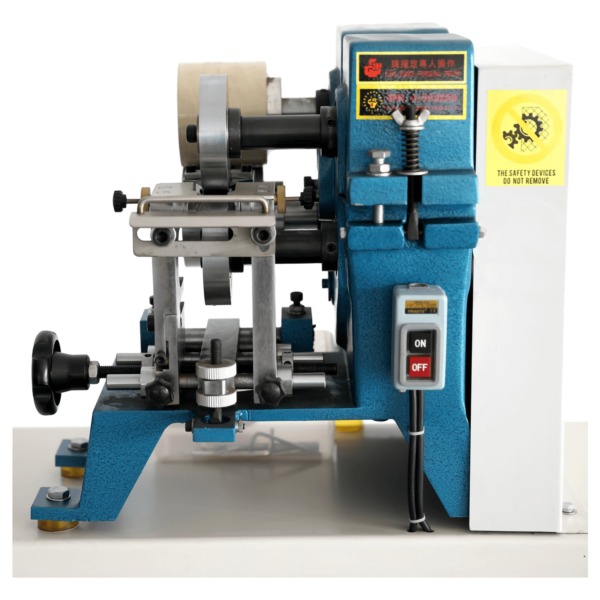

- Dual-Sided Operation: This machine is capable of trimming leather goods on both sides simultaneously, increasing productivity and efficiency in the trimming process.

- Interchangeable Cutting Tools: Different cutting tools, such as fillet and bevel angle, can be easily replaced to achieve various trimming styles and edge finishes.

- Fast Production Speed: The machine is designed for high-speed production, enabling leatherworkers to complete trimming tasks quickly and efficiently.

- Smooth and Tidy Finish: It delivers a precise and clean trimming effect, resulting in leather edges that are smooth and tidy, enhancing the overall appearance of leather products.

Specification

| Model | BS-1111 |

|---|---|

| Working Area | 8-80mm |

| Blade Size | Customizable |

| Net Weight | 150 KG |

| Machine Size | 900 x 430 x 1120mm |

Maintenance

- Regularly clean the machine to remove dust, debris, and excess leather material.

- Lubricate moving parts, as recommended by the manufacturer, to ensure smooth operation.

- Inspect cutting tools for sharpness and replace them when they become dull to maintain trimming quality.

- Check and tighten any loose bolts or connections on the machine.

- Keep the work area well-ventilated, especially when trimming leather materials that may produce dust or fumes.

Safety Considerations

- Operators should receive proper training on safe machine operation, including the use of interchangeable cutting tools.

- Ensure the work area is well-illuminated and free of obstacles to prevent accidents during operation.

- Operators should wear appropriate personal protective equipment, such as safety glasses, when using the machine.

- Turn off the machine and disconnect it from the power source when performing maintenance, blade changes, or adjustments.

FAQs

Can I see a demo of the machine before I buy it?

What is the life of the machine?

What is the warranty period for your machines?

Load More