Your cart is currently empty!

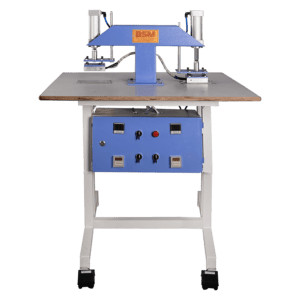

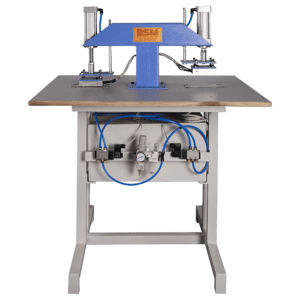

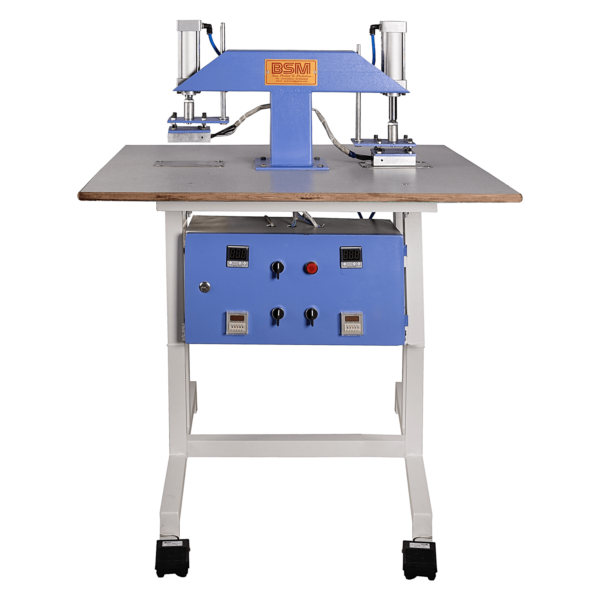

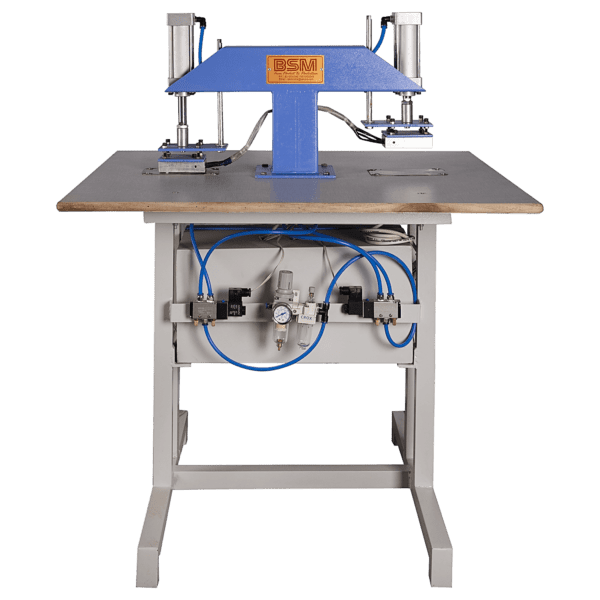

Label Fusing/ Heat Transfer Machine (Double Station) (Pneumatic)

This is a versatile and efficient solution for fusing labels, decals, and heat transfers onto a variety of materials. This machine features double heads, making it ideal for high-volume production. Its pneumatic operation ensures precise pressure and control, while inbuilt digital timers and temperature controllers provide accuracy and consistency in the fusing process.

Description

- Double Head Design: The machine is equipped with two fusing heads, allowing for simultaneous processing of multiple items. This design significantly enhances production efficiency.

- Pneumatic Cylinder: The machine utilizes a pneumatic cylinder to apply pressure evenly during the fusing process. This ensures consistent and high-quality results.

- Double Foot pedal: The double station machine includes a double foot pedal, providing smooth and convenient operation. Operators can control the machine’s functions with ease.

- Digital Timer and Temperature Controller: Inbuilt digital timers and temperature controllers offer precise control over the fusing process. Users can set the desired temperature and duration for optimal results.

Specifications

| Model | BS-9656 |

|---|---|

| Plate Dimensions | 63 x 100 x 25mm |

| Working Table | 800 x 900mm |

| Working Temperature | 100-200 degrees Celsius |

| Pressure | 0.5 – 10 Bar |

| Pneumatic Cylinder | 50 x 80mm stroke Cylinder |

| Power | 1 KW |

| Weight | 42 KG |

Maintenance & Safety

- Ensure that operators are trained in the safe use of the machine and understand the location and function of emergency stop controls.

- Regularly inspect and maintain the machine to ensure proper functionality.

- Clean the working table and heating plates to prevent residue buildup.

- Check and replace any worn or damaged components as needed.

- Follow safety guidelines for working with high temperatures and pressure.

FAQs

Can I see a demo of the machine before I buy it?

What is the life of the machine?

What is the warranty period for your machines?

Load More