Your cart is currently empty!

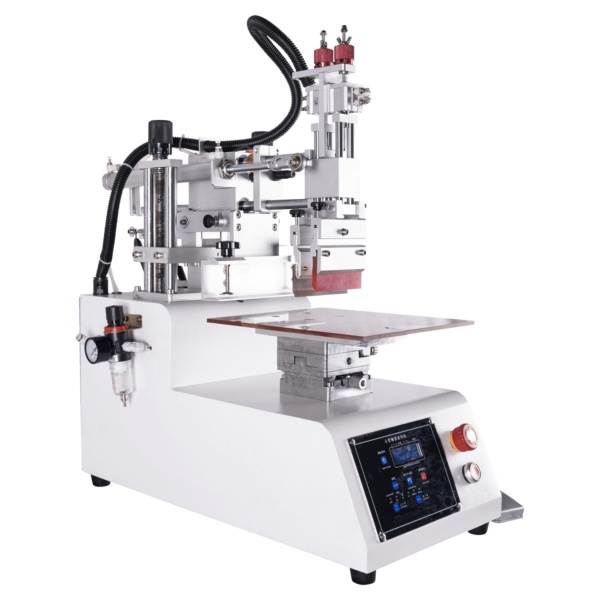

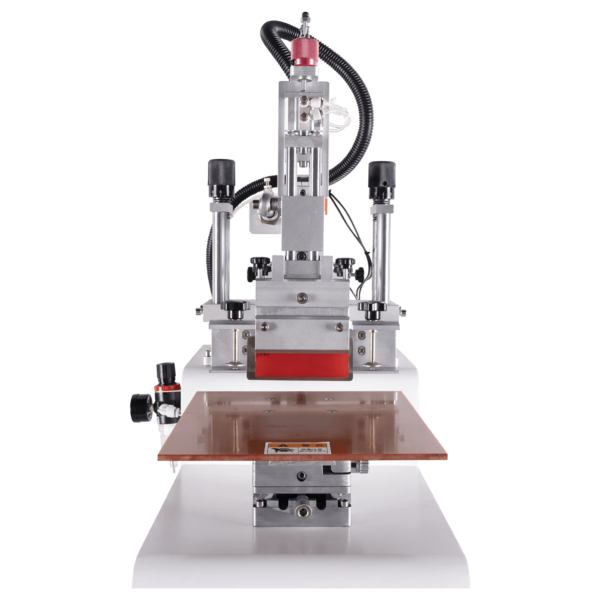

Automatic Screen Printing Machine

This machine is a precision printing solution designed for high-speed and accurate printing on various materials such as metal, glass, plastic, ceramic, and card sheets.

Description

- Stainless Steel Cabinet: Provides durability and protection for the machine body, ensuring long-term reliability.

- Vacuum Working Table: Electroplated to ensure stability and precision during printing, with a built-in 4-digit automatic counter for accurately tracking printing quantity.

- Adjustable Parameters: Cross stroke, spacing, scraper angle, and ink cover blades can be adjusted to customize printing settings according to specific requirements.

- Taiwan Electronic Switch: Allows for precise cross stroke and spacing adjustment, enhancing printing accuracy and consistency.

- Scraper Constant Pressure Equipment: Ensures stable pressure during printing, resulting in uniform and high-quality prints.

- Adjustable Worktable: Enables flexible positioning of the worktable back and forth or right and left, providing versatility for different printing tasks.

- Vacuum Stainless Steel Work Table: Can absorb various film products, enhancing stability and precision during printing processes.

Specifications

| Model Number | BS-840 |

|---|---|

| Maximum Screen Frame Size | 350x300mm |

| Printing Speed | 1200-1300 times/hour |

| Products Height | 100mm |

| Printing Accuracy | ±0.03mm |

| Workbench Vertical and Horizontal Adjustment | 50mm |

| Air Source | 5/6 liters/min (6bar) |

| Power | 220V/110V |

| Outside Dimension | 800x400x750mm |

Maintenance

- Regular Cleaning: Keep the machine clean and free of debris to prevent interference with its operation.

- Lubrication: Lubricate moving parts as needed to ensure smooth and efficient operation.

- Inspection: Regularly inspect components such as the screen frame, scraper, and ink cover blades for signs of wear or damage, and replace if necessary.

- Air Source Maintenance: Maintain the air source system by checking for leaks, cleaning filters, and ensuring proper pressure levels.

- Electrical Safety Check: Regularly inspect electrical components and connections to ensure safe and reliable operation.

Safety Considerations

- Operator Training: Ensure operators are trained on the safe and proper operation of the machine, including adjustment of parameters and emergency procedures.

- Protective Gear: Operators should wear appropriate protective gear, including safety glasses and gloves, to prevent injuries during operation.

- Caution with Moving Parts: Exercise caution when working with moving parts such as the screen frame and scraper to avoid accidents.

- Emergency Procedures: Familiarize all operators with emergency shutdown procedures and first aid measures in case of accidents.

FAQs

Can I see a demo of the machine before I buy it?

What is the life of the machine?

What is the warranty period for your machines?

Load More