Your cart is currently empty!

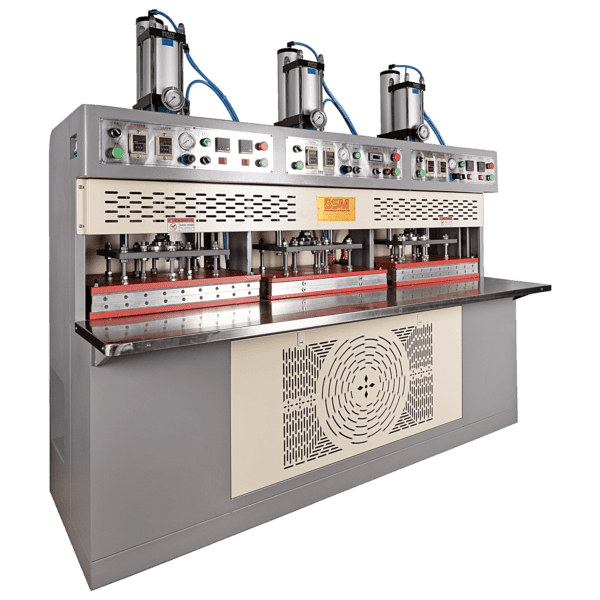

TPU Fusing & Embossing Machine (12 Ton)

This machine is equipped with a Hot and Cold System, offering a hydro-pneumatic solution for efficient and precise TPU fusing. Its adjustable heating and cooling temperature, pressure, and pressure timing enable optimal results for various TPU applications.

Description

- Hot and Cold System: Ensures strong and durable fusing with effective bonding and quick cooling of TPU materials.

- Adjustable Heating Temperature: Precisely control the fusing process for different TPU materials, ensuring optimal bonding without compromising integrity.

- Adjustable Cooling Temperature: Efficiently cool and solidify the fused TPU materials, enhancing strength and durability.

- Adjustable Pressure and Pressure Timing: Customize pressure and its duration during fusing for precise and consistent results.

- Hydro Pneumatic Operation: Smooth and reliable performance with consistent pressure, reducing operator fatigue and enhancing productivity.

Specifications

| Model No. | BS-605 |

|---|---|

| Voltage | AC380V/50HZ |

| Power | 20KW 3 Phase |

| Running Load | 12-13 Kw |

| Air Pressure | 0.5 MPA |

| Chiller Capacity | 2 Ton |

| Temperature Accuracy | +3°C |

| Plate Pressure | 12 Ton (Double Pressure) |

| Working Area | 406 x 609 mm |

| Fusing Time | 8-30 Second (Depends On The Type of Material) |

| Heating Plate | Top & Bottom Heating |

| Cooling Plate | Top & Bottom Cooling |

| Machine Size (mm) | 2000 x 1930 x 863 mm |

| Net Weight | 1450 kg |

Maintenance

- Regular Cleaning: Remove dust, debris, or adhesive residue from the machine using appropriate cleaning agents and tools.

- Lubrication: Lubricate pneumatic components and moving parts to maintain smooth operation and prolong the machine’s life span.

- Inspection and Adjustment: Regularly inspect for wear, loose connections, or damaged components. Tighten or replace parts as needed.

- Trained Operator: Provide comprehensive training on machine maintenance procedures to operators, including cleaning, lubrication, and routine inspections.

Safety Considerations

- Operator Protection: Prioritize operator safety with appropriate safety goggles, gloves, and protective clothing. Operators should follow all safety guidelines.

- Electrical Safety: Ensure proper grounding and stable power source connection. Avoid exposure to water or moisture and inspect electrical components regularly.

- Hot Surface Hazards: Avoid direct contact with hot surfaces and allow sufficient time for cooling before maintenance or adjustments.

- Temperature Control: Use the recommended temperature range for the material being fused. Calibrate and monitor temperature controls regularly.

- Ventilation: Maintain proper ventilation in the working area to dissipate fumes or heat. Ensure the exhaust system functions effectively and the workspace is well-ventilated.

FAQs

Can I see a demo of the machine before I buy it?

What is the life of the machine?

What is the warranty period for your machines?

Load More